Materials 4.0: make your forging processes sustainable and energy efficient

In this article Grupo SPRI, together with the BDIH and its Advanced Materials Node, continues develop our knowledge and capacity to innovate metal manufacturing processes through forging technology, and in particular to the techniques and solutions that make them increasingly sustainable.

In the previous article, we detailed how to use novel techniques and materials in forging processes to meet the new market demands related to lighter parts, fewer defects and a lower cost of production and maintenance.

In this next instalment we present a sample of techniques and assets that allow, in addition, the reduction in raw material consumption and increased sustainability and energy efficiency in forging processes.

For example, node member, AZTERLAN, has developed a heat treatment methodology, which makes it possible to utilise the residual heat of forged pieces in processes and plants with space limitations. Added to this is demonstration, in close collaboration with companies in the sector, energy savings of 75% implementing this methodology compared to conventional thermal treatment. Assets, such as its Pilot Casting Plant in which the rapid prototyping of new components can be carried out according to the customer’s requirements, are available to support companies in such projects.

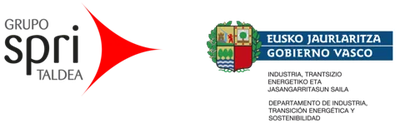

For its part, CEIT, the organization that coordinates the advanced materials node of the Basque Digital Innovation Hub, has several assets that offer techniques for this sector and purpose. Among them, the High-temperature unit for the forming, treatment and controlling the behaviour of materials provides the answer to the optimisation of processes in the heat forming of materials and its improvement under operational or high-performance conditions. Specifically, it deals with the thermomechanical processing of steels and other alloys.

The two types of services of interest to the forging sector are: firstly, analysis of the behaviour of materials under extreme service conditions (“harsh”) and various degradation and failure mechanisms, such as ageing, oxidation and corrosion; secondly, exploration of hot forming processes and heat treatments, as well as new manufacturing routes through optimised compositions and improved rolling sequences (flat/long products), forging and extrusion.

The solutions presented in this article are highly complementary with those laid out in the last example, and serve as an example of how the Advanced Materials Node of the BDIH enables transforming companies to adapt their processes to technologies with greater added value, and more efficiency both energy-wise and economically in terms of consumption of materials.

If you are interested in deepening your knowledge of what the Advanced Materials Node of the BDIH offers, follow this series of articles on Materials 4.0 where we tell you in detail which are the capacities, assets and services of the node in a practical, applied way.

And contact the BDIH to find out how we can bring your company closer to the solutions that interest you most.